Product: High Temperature Accelerometers

Key Features:

Reliability is crucial for success in the challenging oil and gas industry, where risks are frequent and can significantly impact opportunities. Dependable, precise data can determine whether a venture succeeds or fails.

Ericco has been supplying robust sensing products to the global oil and gas sector, proving their exceptional reliability and accuracy in some of the world’s most demanding environments.

High temperature accelerometers are designed to withstand harsh conditions and provide accurate data in demanding industries such as aerospace and oil & gas. Essentially, their purpose is to function effectively in challenging environments, including underground settings and extreme temperatures.

Manufacturers of high temperature accelerometers employ specific technologies to ensure the sensors’ reliability in extreme conditions. For instance, Micro-Magic Incs Quartz Accelerometer for Oil and Gas is proved to own high performance. This model utilizes an amorphous quartz proof-mass structure that reacts to acceleration through flexure motion, ensuring excellent stability in bias, scale factor, and axis alignment.

High temperature accelerometers are vital in industries where equipment must endure extreme conditions. Their robust design and advanced technology enable them to operate reliably in harsh environments, providing crucial data that enhances safety, efficiency, and performance. Here’s a closer look at their applications and significance:

In the oil & gas industry, high temperature accelerometers are essential components of Measurement While Drilling (MWD) systems. MWD is a well logging technique that uses sensors within the drillstring to provide real-time data, guiding the drill and optimizing drilling operations. These accelerometers can withstand the intense heat, shock, and vibrations encountered deep underground. By delivering accurate measurements, they help.

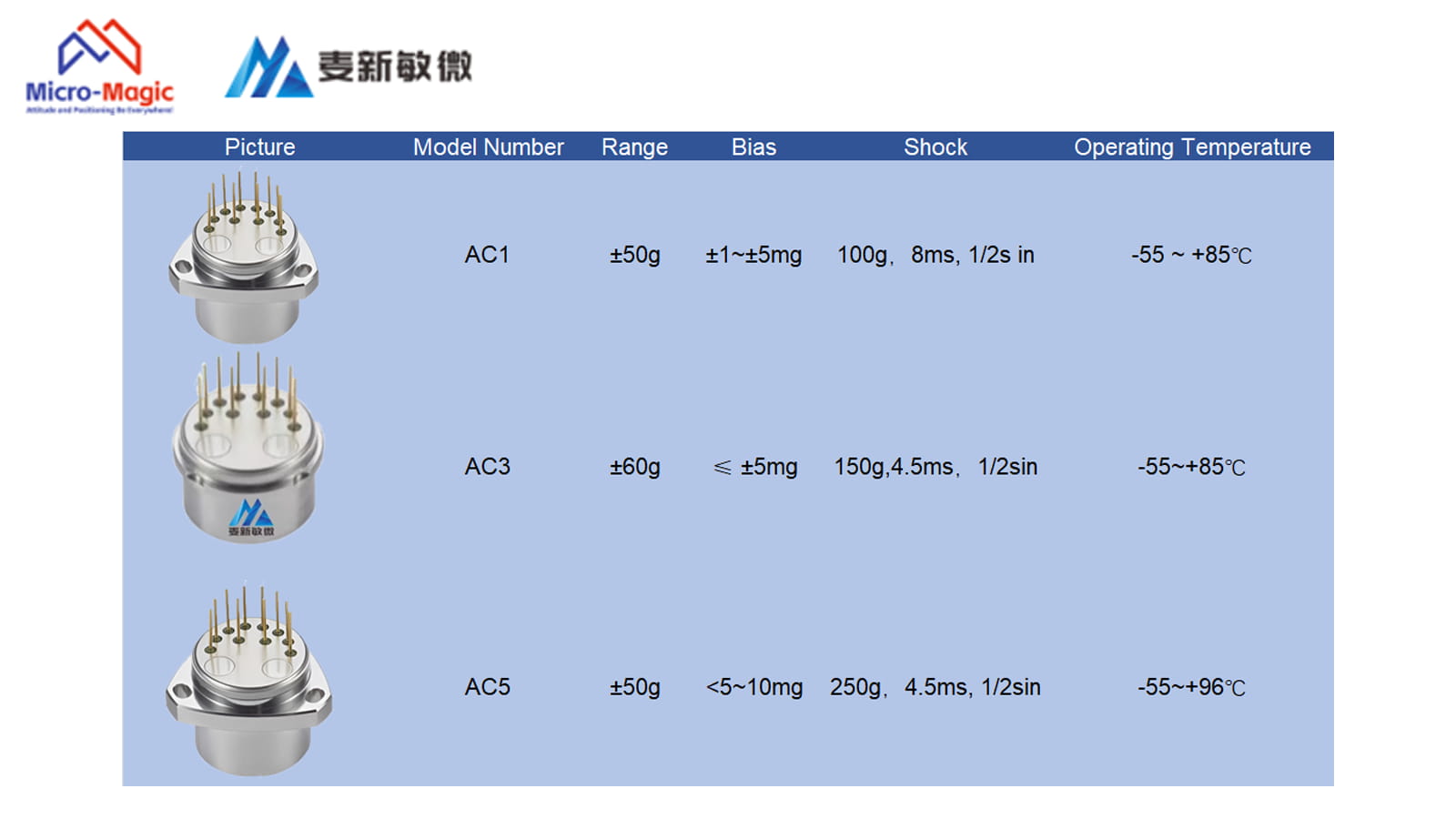

Fig.1 High Temperature Accelerometers

In the aerospace industry, high temperature accelerometers are used to monitor the performance and structural integrity of aircraft. They can endure the extreme conditions of flight, including high temperatures and intense vibrations, and are crucial for

In automotive testing, high temperature accelerometers are employed to measure vehicle dynamics and structural integrity under extreme conditions. They are particularly useful for:

Crash Testing: Monitor acceleration and deceleration forces during crash tests to evaluate vehicle safety and crashworthiness.

High-Performance Testing: Measure vibrations and stresses in high-performance vehicles to ensure components can withstand extreme driving conditions.

Durability Testing: Assess the long-term durability of automotive components by subjecting them to prolonged high temperatures and vibrations.

Beyond oil & gas, aerospace, and automotive industries, high temperature accelerometers are also used in various other industrial applications where equipment operates in extreme conditions. These include:

Power Generation: Monitor vibrations in turbines and other equipment to ensure optimal performance and prevent failures.

Manufacturing: Measure vibrations and stresses in heavy machinery to maintain operational efficiency and safety.

Robotics: Provide precise data on the movements and stresses experienced by robots operating in high-temperature environments, such as those used in welding or foundries.

Micro-Magic Inc has excelled in designing and manufacturing high-temperature accelerometers that meet the demanding requirements of these industries. We offer solutions tailored for energy exploration and other high-temperature applications. These accelerometers feature:

Analog Output: For easy integration with existing systems.

Mounting Options: Square or round flanges to suit different installation needs.

Field-Adjustable Range: Allowing customization to specific application requirements.

Internal Temperature Sensors: For thermal compensation, ensuring accurate measurements despite temperature variations.

What’s more, Micro-Magic Inc’s Quartz Accelerometer for Oil and Gas is proved to own high performance. This model utilizes an amorphous quartz proof-mass structure that reacts to acceleration through flexure motion, ensuring excellent stability in bias, scale factor, and axis alignment.

Some high temperature accelerometers also incorporate external amplifiers to safeguard the sensor from heat damage.

And we recommend the AC1 for oil and gas, whose operating temperature is -55 ~ +85 ℃, with an input range of ±50g, bias repeatability <30μg, and scale factor repeatability <50 ppm.

High temperature accelerometers are indispensable in industries that operate under extreme conditions. Their ability to provide reliable and accurate data in such environments enhances operational efficiency, safety, and performance. With advancements in technology, these sensors continue to evolve, offering even greater reliability and precision in the most demanding applications.

Xml Privacy Policy Blog Sitemap

copyright @ Micro-Magic Inc All Rights Reserved.

Network Supported

Network Supported