Three-Axis Hall Sensor: The Key Solution for Precision Angle Measurement in Modern Technology

In the field of magnetic sensing technology, three-axis Hall sensors are sparking a precision revolution. This type of sensor achieves true three-dimensional spatial magnetic vector measurement by simultaneously detecting the magnetic field strength in the X, Y, and Z axes, completely breaking through the limitation of traditional single axis Hall sensors that can only detect vertical magnetic fields. The core technology lies in depositing special magnetic flux concentration materials (IMC®) onto the surface of CMOS chips. Enable sensors to capture magnetic field components parallel to the chip surface, combined with high-precision signal chain processing, to achieve 360° full angle position detection. This non-contact measurement method avoids mechanical wear and significantly improves long-term stability and reliability in harsh environments, bringing unprecedented precision control capabilities to modern industry and consumer electronics.

■ High Precision and Resolution: The resolution reaches 14 bits (digital signal), equivalent to a resolution of 0.022 °, which is much higher than traditional optical encoders. The typical linearity error is ±1°, and the accuracy is maintained at 10 bits (0.35 °) after temperature drift compensation. The G830 angle sensor even achieves 16 bit ADC accuracy, with an angle error of only 0.02 ° and a temperature drift of 0.002 °/C, reaching the international leading level.

■ Exceptional Environmental Robustness: With strong temperature adaptability, resistance to mechanical tolerances and stray magnetic fields, the working temperature range can reach -40 ° C to+160 ° C, and is insensitive to magnet eccentricity and air gap changes (± 50% tolerance). The third-generation technology can resist stray field interference of 4 kA/m (such as electric vehicle motor magnetic field) and eliminate external interference through differential algorithms.

■ System Integration and Cost Optimization: No PCB packaging, supports direct soldering solutions such as DMP-4 (dual-mode packaging) and SMP-3 (single-mode packaging), eliminates the need for PCB boards, improves EMC/ESD reliability, and reduces system costs. Flexible magnetic circuit design, compatible with various types of magnets with radial/axial magnetization (ferrite, neodymium iron boron, etc.), smaller size and no need for complex calibration.

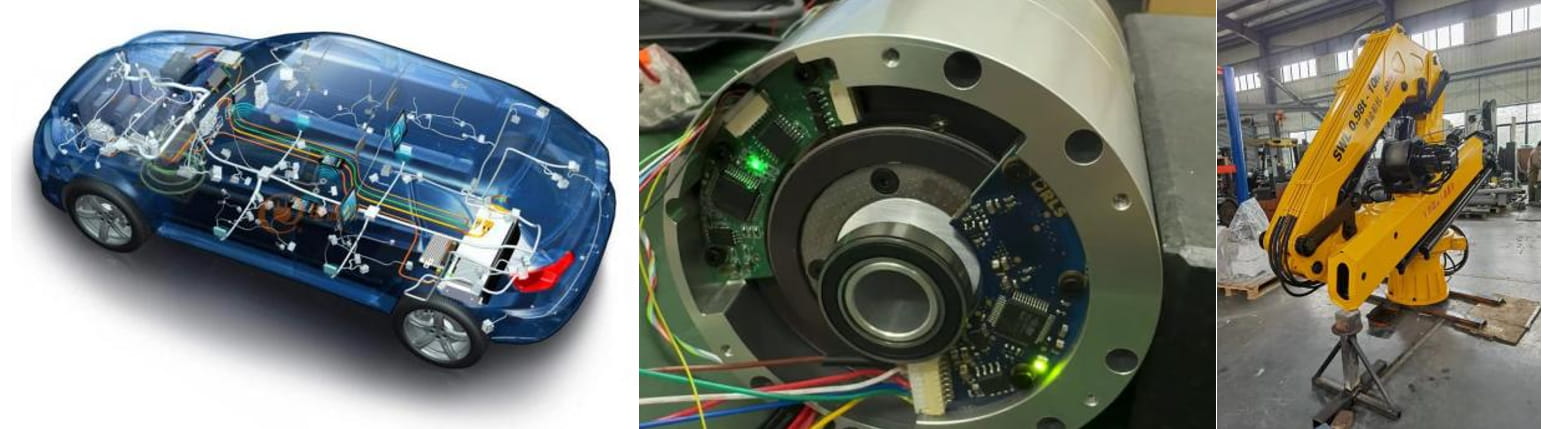

In the field of automotive electronics, three-axis Hall sensors have penetrated into key nodes of power transmission:

■ Chassis and safety system: steering wheel torque/steering angle detection (EPS), electronic brake pedal position sensing, accuracy directly affects the stability control efficiency of the vehicle body.

■ Powertrain control: Electronic throttle body, EGR valve angle feedback, with an error of ± 1° to ensure precise emission control.

■ New electric architecture: motor rotor position detection (replacing photoelectric encoders), gearbox gear position sensor.

■ Robot joint coding: realizes the detection of robotic arm posture, real-time monitoring of collaborative robot joint angles (0.1° repeatability accuracy), and adapts to industrial environments with anti oil pollution characteristics.

■ Motor control: BLDC motor commutation angle detection, replacing optical encoders.

■ Heavy machinery equipment positioning: Crane arm angle sensing, forklift lifting height detection, agricultural machinery steering angle feedback, IP equivalent protection against dust and water vapor erosion.

Micro-Magic Inc has produced a series of angle sensor products based on three-axis Hall technology, ranging from low to high precision, from low to high cost. Each product undergoes calibration, reverse and anti pulse peak voltage protection, and long-term aging stability testing before leaving the factory. Each process is precise and rigorous, ensuring reliability under different working conditions and long-term use cycles.

Angle Sensor Performance Indicators

|

Parameter |

G803 |

G810 |

G830 |

Unit |

|

Measuring range |

0~360 ° |

0~360 ° |

0~360 |

° |

|

Temperature drift |

0.02 |

0.01 |

0.002 |

|

|

Resolution |

0.05 |

0.01 |

0.01 |

° |

|

Accuracy |

1 |

0.5 |

0.05 |

° |

|

Impact resistance |

20000g,0.5ms,3 times/axis |

|||

|

Anti-vibration |

10grms,2~2000Hz |

|||

|

Noise |

5mV |

|||

|

Average working time |

≥55000h |

|||

|

Output |

Digital TTL, RS232, RS485, RS422, CAN optional Voltage 0~5V, 0.5-4.5V, 0~10V optional Current 0-20mA, 4-20mA optional |

|||

|

Working temperature range |

-40~85℃ |

|||

The three-axis Hall angle sensor, with its non-contact, high-precision, and multi-dimensional technological advantages, is quietly reshaping the underlying architecture of multiple industries. With the breakthrough of technological bottlenecks, especially the improvement of anti-interference ability and the integration of edge intelligence, this technology will develop towards miniaturization and intelligence, providing a more reliable "spatial perception eye" for the era of Internet of Things.

Xml Privacy Policy Blog Sitemap

copyright @ Micro-Magic Inc All Rights Reserved.

Network Supported

Network Supported