Product: NF1000 Gyro North Finder

Key Features:

Conclusion: The NF1000 delivers fast, precise north seeking and orientation, making it a valuable tool for directional drilling, military navigation, and other engineering applications.

In military and civilian orientation, north finder is widely used. It can determine the north in static all-weather, all-round, fast and real-time, so as to determine the carrier azimuth, that is, the angle between a reference axis of the carrier and the true north direction, which is used as the azimuth reference for observation, target aiming and navigation system reset. It can also be used as a bearing reference for underground operations such as tunnels and mines in military applications, especially requiring the gyro north finder to achieve fast and accurate orientation in a short time.

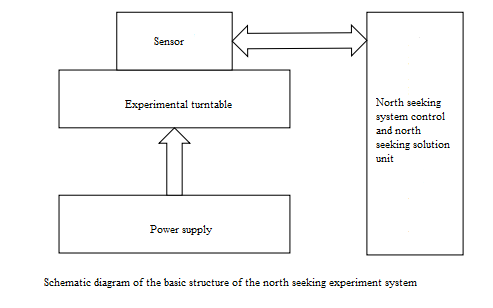

The north finder uses the gyroscope to calculate the angle between the carrier and the true north direction. This system uses a gyroscope and a quartz flexible accelerometer to form a strap-down system. The sensitive axis of an accelerometer is parallel to the sensitive axis of the gyroscope. The other is along the horizontal plane orthogonal gyro and accelerometer to form an inertial assembly relative to the installation base around the vertical axis according to the command of the control system rotation of the assembly around the vertical axis rotation two positions can be solved to measure the azimuth acceleration of the inertial assembly to compensate for the vertical component of the earth rotation angular velocity.

Oil drilling and development is a high-investment, high-risk, high-return, technology-intensive, capital-intensive industry, decision-making or operational mistakes will cause huge economic and social losses.

With the improvement of the exploration level of oil and gas on land and sea, the types of oil and gas reservoirs have become complicated and diversified, the proportion of low and ultra-low permeability oil and gas reservoirs has increased year by year, and the well depth has developed from shallow and medium deep to deep and even ultra-deep. The types of oil and gas reservoirs are extended from conventional to unconventional. The sedimentary type expanded from continental to Marine. Exploration and development work has entered the stage of low, deep and difficult, which poses new challenges to oil and gas exploitation. In this case, the continuous use of vertical well technology will not meet the needs of modern drilling, so the directional drilling technology came into being.

Directional drilling has always been considered “the process and science of deflecting a well in a specific direction in order to drill to a predetermined underground target.” As shown by the drilling directional north finder, azimuth angle and inclination angle are two key parameters for drilling hole positioning. The key performance indexes of gyroscope and accelerometer can be tested and calibrated automatically by using the built gyro north finder software.

During drilling construction, the drilling rig arrives at the designated drilling site. According to the designed azimuth and inclination angle, the operator roughly predetermined the orientation and inclination Angle of the drilling rig, and then placed the north finding instrument at the horizontal place near the drilling site for north seeking operation; After the north finding is completed, the north seeker is placed on the guide rail of the rig to display the current rig attitude information (inclination angle and azimuth angle), and then the rig attitude is adjusted until the rig reaches the design angle.

According to the problems we encountered in the drilling survey process, we launched a new shaped north finder NF1000, specially for petroleum mining, directional drilling and other engineering applications, it not only achieved a breakthrough in appearance, but also from the volume and weight have been greatly improved, its size is only mm Φ31.8 x85 mm, The weight is 400g, which has achieved a great breakthrough in the traditional inertial products of the North finder series. Its emergence allows more engineers to face more difficult, more limited space monitoring environment.

Micro-Magic Inc north seeker uses a strap-down system. For the zero deviation drift and random error of the north finder, Micro-Magic Inc company has carried out many product technical reforms. At present, the latest north seeker NF1000 not only carries out inclination compensation and self-alignment functions, but also can be used in the probe. More limited monitoring space is facilitated. If you are interested in this product, please discuss it with us.

Xml Privacy Policy Blog Sitemap

copyright @ Micro-Magic Inc All Rights Reserved.

Network Supported

Network Supported