A5500 series is an IMU/VRU/AHRS sensor composed of high-performance MEMS-IMU, magnetometer, and enhanced single axis gyroscope. It is equipped with self-developed adaptive extended Kalman filter, IMU noise dynamic analysis algorithm, and carrier motion state analysis algorithm, which can meet the accuracy of attitude angle under high dynamic conditions and reduce heading angle drift. Every sensor undergoes fine compensation including temperature, zero bias, scaling factor, and cross axis before leaving the factory.

Part No, :

A5500Order(MOQ) :

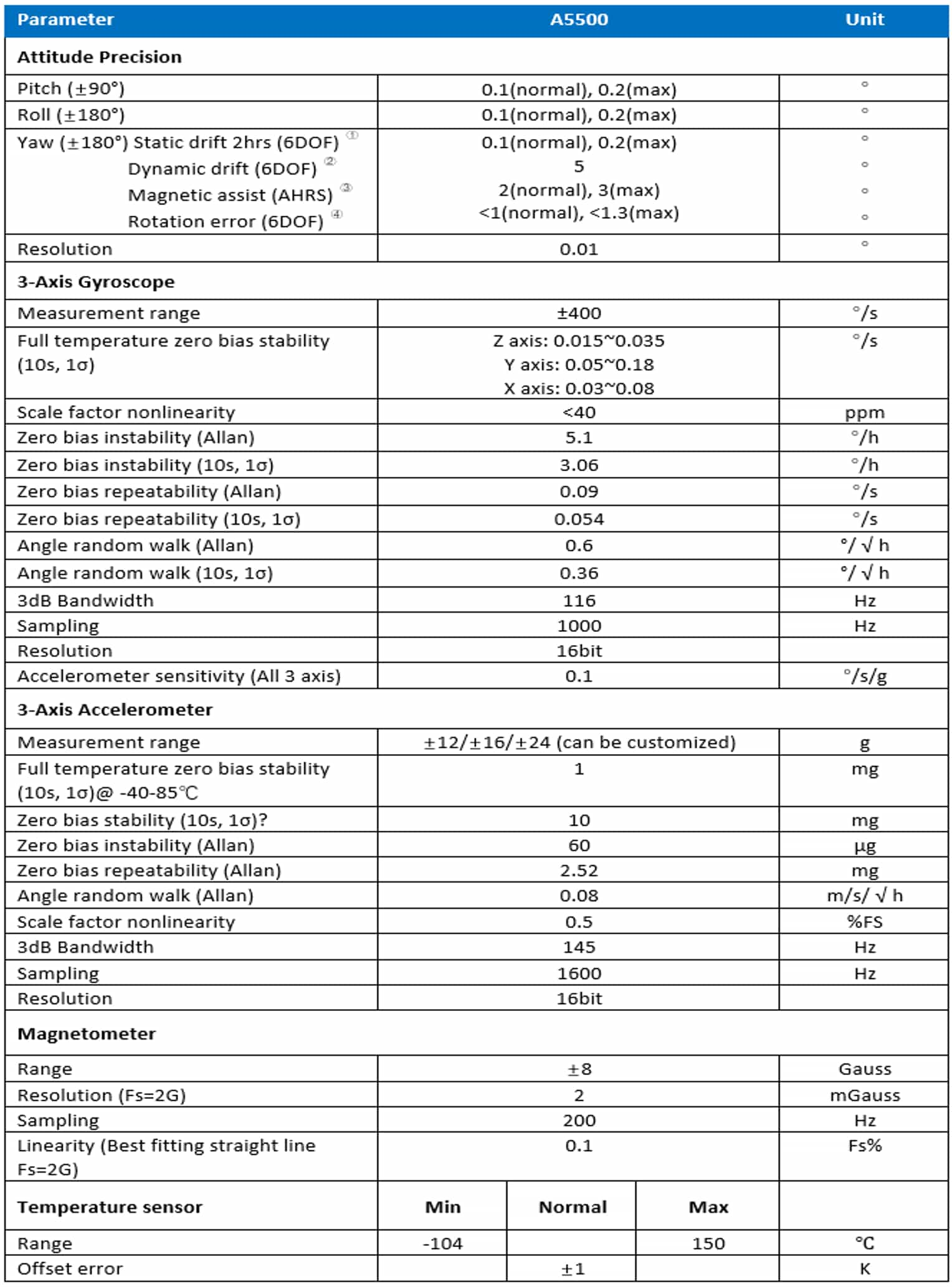

1Product Series and Parameters

Production process

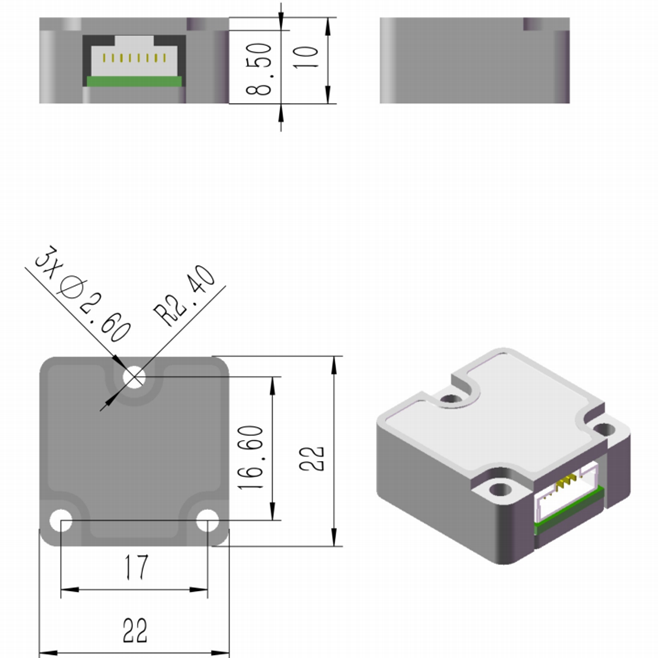

Product dimension

Application Scenarios

FAQ

Xml Privacy Policy Blog Sitemap

copyright @ Micro-Magic Inc All Rights Reserved.

Network Supported

Network Supported